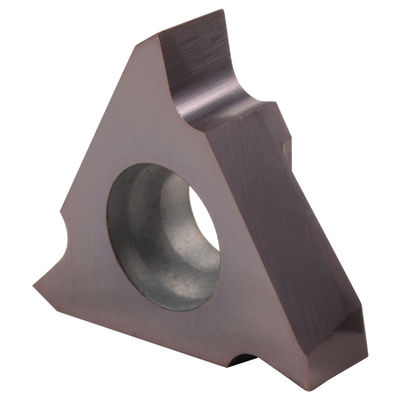

Inserções de ranhura de carboneto TGF32 GTMH32GX-050R para torno CNC

Campo de Aplicação

A série GTMH32-GX de pastilhas de metal duro para canal é projetada para operações de torneamento e canal em tornos e máquinas CNC, disponíveis em vários formatos e ângulos de corte.

Padrão de produção

Os tamanhos das pastilhas podem ser personalizados de acordo com os requisitos do cliente, aderindo a padrões que incluem:

- TGF32:Série Kyocera TGF32 - nossa referência de produção padrão

- GTMH32:Série NTK com especificações semelhantes ao TGF32

- "GX" denota uma subsérie, enquanto "050R" indica especificação e orientação de corte

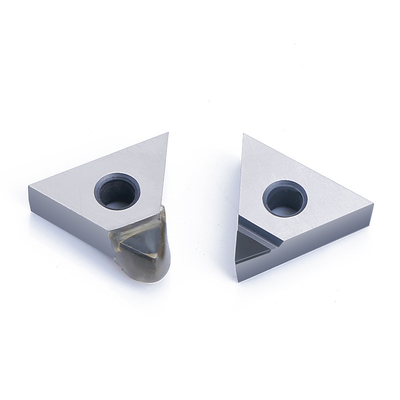

Detalhes do produto - GTMH32-GX

- Material:Pó de metal duro 100% original para maior resistência ao desgaste e tenacidade

- Dimensões:CW: 0,33-2,50 mm | CDX: 0,8-2,50 mm | RE: 0,05-0,10mm

- Revestimento:Tecnologia avançada de revestimento para resistência à corrosão e ao desgaste

- Moagem:Superfície de alta suavidade com arestas de corte de qualidade para reduzir o atrito

- Ajustar:Tiras de borda precisas minimizam a vibração durante a operação

- Materiais:Não revestido para alumínio/metais não ferrosos; Revestido para aço/ferro

- Personalização:Disponível para requisitos fora do padrão com desenhos CAD/3D

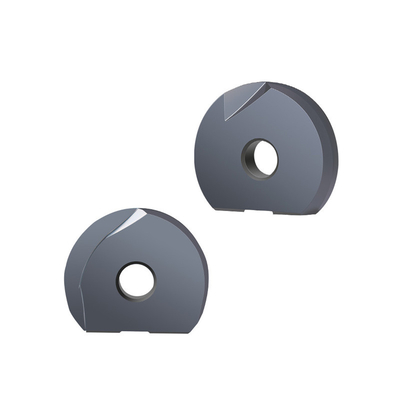

Recursos do produto

- Aresta de corte chanfrada com processamento de arco de ponta para proteção da aresta

- Revestimento composto de alto desempenho para superfícies duras e lisas

- Design eficiente de quebra-cavacos para desempenho de corte ideal

- Dimensões precisas garantem ajuste perfeito com porta-ferramentas

- Material base de origem europeia para resistência à oxidação e ao desgaste

- Projetos personalizados disponíveis para dimensões, revestimento e quebra-cavacos

Especificação do produto

| Número da peça |

CW (mm) |

CDX (mm) |

RE (mm) |

Porta-ferramentas aplicáveis |

| TGF32 R/L |

0,33-2,50 |

0,8-2,5 |

0,05-0,10 |

KTGF R/L S...KTGF R/L GTT R/L NGT... R/L |

Observação:Tamanhos padrão mostrados; dimensões personalizadas disponíveis de acordo com os requisitos do cliente.

Processo de Produção

- Sinterização com pó de metal duro 100% original

- Usinagem de retificação plana

- Usinagem de retificação circundante

- Criação de ponta

- Chanframento de arestas e processamento de arco de ponta

- Aplicação de revestimento composto

Inspeção de Qualidade

Por que escolher nossos produtos

- Inovação técnica para precisão de superfícies complexas

- Processamento rápido e prazos de entrega confiáveis

- Alta precisão (tolerância de 0,005-0,001 mm)

- Medidas rigorosas de confidencialidade, incluindo opções de NDA

- Instalações de produção avançadas com múltiplas linhas

- Preços competitivos para qualidade superior

Perguntas frequentes

Q1: A confidencialidade da nossa cooperação é garantida?

R: Sim, todas as informações, incluindo detalhes e desenhos da empresa, permanecem confidenciais. Podemos assinar um NDA, se necessário.

Q2: Quais são as suas condições de pagamento?

R: Depósito de 30% via T/T, com saldo de 70% pago antes da entrega após a aprovação das fotos do produto.

Q3: Como a qualidade do produto é garantida?

R: Inspeção 100% dos primeiros lotes, com testes de matérias-primas e verificações de produção antes do envio.

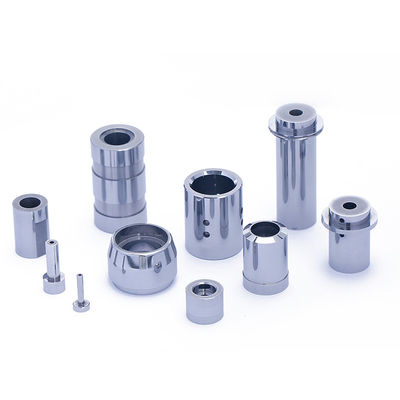

Q4: Que outros produtos você oferece?

R: Fornecemos pastilhas de metal duro, fresas de topo, brocas, ferramentas de mandrilamento e moldes de precisão personalizados.

Q5: Estão disponíveis descontos por volume?

R: Sim, oferecemos preços competitivos e descontos para pedidos de grandes quantidades.

Q6: Você aceita pedidos de pequenas amostras?

R: Sim, o MOQ da amostra é uma peça com prazo de entrega de 2 a 3 dias para itens padrão.

Q7: Qual embalagem é usada?

R: A embalagem padrão inclui caixas plásticas à prova de choque em caixas, com opções personalizadas disponíveis.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!