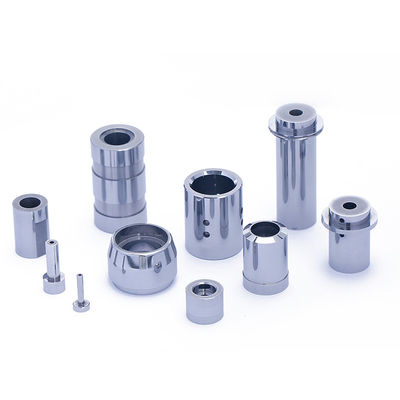

Componentes de Moldes de Punção de Alta Resistência ao Impacto Rolamento de Carboneto de Tungstênio

Descrição do Produto

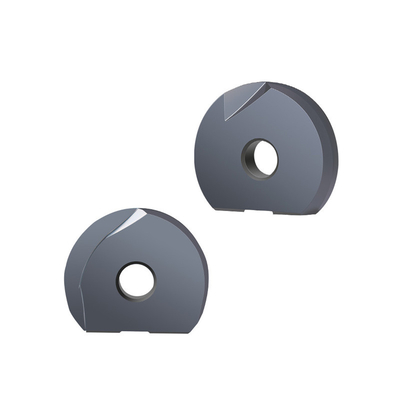

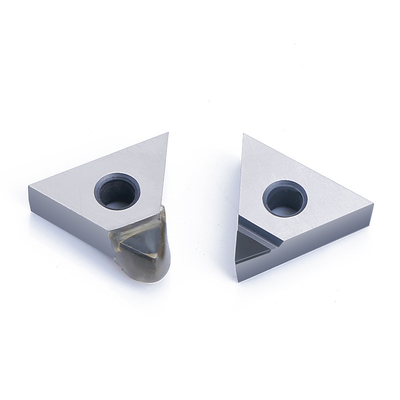

Ferramentas de Rolamento de Carboneto de Alta Resistência ao Impacto Para Produção de Rolamentos, Rodas e Anéis

Campo de Aplicação

Ferramentas de Rolamento de Carboneto, uma das matrizes de forjamento, são usadas para processamento de rolamentos de metal, rodas, anéis, esferas circulares e esferas cônicas, de alta tenacidade à resistência ao calor, de acordo com a solicitação do cliente. Nossa Kinyet se concentra em melhorar a vida útil das ferramentas e está sempre apta a oferecer aos clientes soluções econômicas.

Detalhes do Produto - Ferramentas de Rolamento de Carboneto

- Rugosidade da Superfície: RZ~~0.2um / F1.0mm/min

- Precisão: ±0.001mm

- Personalização: Absolutamente personalização. Não há estoque padrão para esta série de produtos, e apenas pedidos não padronizados são aceitos. Por favor, anexe desenhos CAD/desenhos 3D à sua consulta.

Material Adequado

Carboneto de tungstênio, cerâmica e HSS, etc., propriedades como abaixo:

| Material |

Propriedades do Material |

| Carboneto |

O carboneto cimentado é um compósito metalúrgico em pó que consiste em uma ou mais fases de material duro (por exemplo, carboneto de tungstênio) e um material de ligação (por exemplo, cobalto). É um material extremamente duro, caracterizado por alta resistência ao desgaste e estabilidade térmica. É usado em vários campos que exigem ferramentas ou componentes particularmente resistentes ao desgaste. Em comparação com o aço para matrizes, é mais difícil de usinar e tem um custo de material mais alto, mas sua vida útil é frequentemente várias vezes maior do que a do aço para matrizes. |

| Cerâmica |

Os materiais cerâmicos têm boa resistência a altas temperaturas e desempenham um papel decisivo em aplicações de alta temperatura na faixa de temperatura de operação contínua de 180 °C a mais de 1200 °C. Em comparação com os materiais metálicos, as cerâmicas de óxido são consideradas resistentes ao ataque químico, especialmente em soluções ácidas e alcalinas. Os comuns incluem alumina, zircônia, carboneto de silício, cerâmicas de nitreto de silício. |

| HSS |

Aço rápido com resistência superior à abrasão e tenacidade para uso geral. É usado principalmente em produção de pequenos lotes ou campos com altos requisitos de tenacidade do material. |

Envolver Tecnologia de Usinagem

- Envolver Tecnologia de Produção: Retificação cilíndrica, retificação circular interna, retificação de perfil óptico, retificação plana, usinagem de roscas, corte de fio de velocidade média, corte de fio de baixa velocidade, usinagem por descarga de espelho e assim por diante.

Por que nos escolher

- Tecnologia Avançada: Formas complexas e várias estruturas podem ser formadas rapidamente e mantidas precisas.

- Processamento Eficiente: Ciclo de produção curto e entrega rápida, para garantir o cronograma de envio de acordo com a data de entrega.

- Qualidade do produto: Qualidade consistente garantida. Alta precisão, até ±0.003mm.

- Sistema de confidencialidade: Medidas triplas de confidencialidade para proteger. Se precisar, podemos assinar um NDA (Acordo de Não Divulgação), comprovando mais segurança.

- High-end e totalmente equipado: Capacidade de processamento excepcional, múltiplas linhas de produção, equipamentos avançados, instalações de suporte profissional.

- Custo-benefício: Design razoável e seleção de materiais nos levam a um preço competitivo, para que possamos ajudá-lo a oferecer um preço mais favorável dos produtos do mesmo nível.

A Kinyet se concentra em pesquisa e desenvolvimento de materiais relevantes de tungstênio o tempo todo. Ao introduzir constantemente novas tecnologias e aumentar o investimento em equipamentos de produção de ponta, a Kinyet é capaz de oferecer soluções de moldes com alta relação qualidade-preço, incluindo alta precisão, maior vida útil das ferramentas e custo-efetividade, etc. Agora, a Kinyet foi fundida com a Drow. Com esta combinação poderosa, acreditamos que criaremos produtos mais excelentes para os consumidores no futuro!

Critérios de Qualidade

- Resistência ao Desgaste

- Precisão

- Resistência à Corrosão

- Resistência ao Impacto

- Tenacidade

- Módulo de elasticidade, Rigidez

- Resistência à Ruptura Transversal. Etc.

FAQ

P1: Você produz moldes de punção especiais ou componentes de matriz de punção?

R: Sim, somos especializados na fabricação de moldes personalizados e traduzimos a ideia de matrizes de punção mais complexas em realidade, os componentes de moldes de punção fabricados por nós são projetados e personalizados para várias aplicações exigentes e variedade de materiais!

P2: Você aceita baixo volume para pedidos de amostra? E qual é o seu MOQ para personalização?

R: Sim, aceitamos. Para pedidos de amostra, MOQ de uma peça é aceito. Por favor, anexe desenhos CAD/desenhos 3D à sua consulta e o prazo de entrega da amostra é de 10 a 15 dias. Pode ser negociado para outros requisitos especiais.

P3: Se quisermos cooperar com você, é possível obter confidencialidade?

R: Claro, todas as suas informações, incluindo informações da empresa, desenhos, detalhes do PO, serão mantidas confidenciais, podemos assinar um NDA se você quiser (acordo de não divulgação).

P4: Quais são seus termos de pagamento?

R: T/T 30% como depósito e 70% de saldo antes da entrega. Mostraremos as fotos dos produtos e embalagens antes de você pagar o saldo.

P5: O que você pode comprar de nós?

R: Pastilha de carboneto, fresa de topo de carboneto, broca de carboneto, mandrilamento de carboneto, ferramentas de corte e moldes de precisão de carboneto personalizados.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!